Self standing cable troughing system SP

The GRP Ebo Systems cable troughing SP is an innovative product particularly suitable in the facilities, impassable infrastructure, inaccessible environments, or dented places.

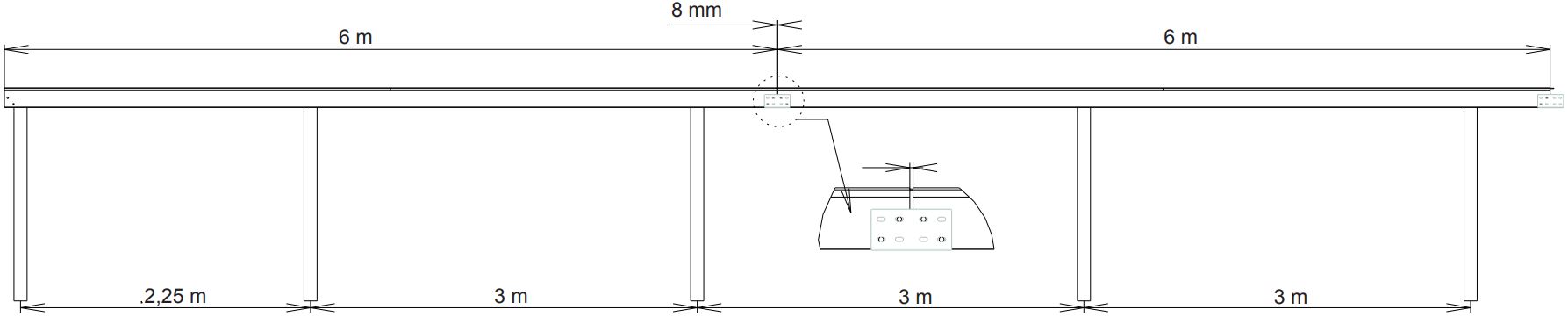

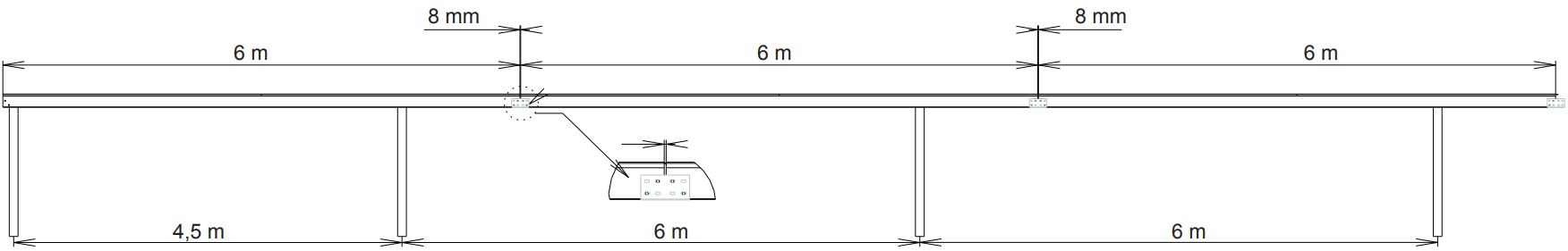

A flexible and economical installation due to the use of a system for supporting and fixing HDG. Lightweight lengths of 6m, perforations and lateral sides of the preassembled connecting fasteners allow a quick and easy installation.

Application areas: railways, trains, subways, etc..